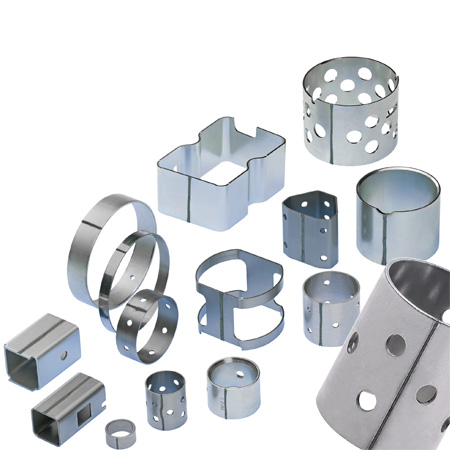

For more than 30 years the firm of Dömer has been designing and making the dies and tools for the products of our customers in-house. Our team of three experienced designers ensure the reliable conceiving and designing of the tools/dies - from the layout of the part to be produced, via the process development through to the detailing of the design. For this the most modern CAD systems as specially developed for forming technology are used. The selection of the right material as well as of the coating that might be needed for components subjected to severe loads such as male and female dies, etc. is carried out in co-operation with our associate company, namely Messrs. Dörrenberg Edelstahl GmbH (www.doerrenberg.de).

The realization of the design is also carried out in our own tool-making department. Modern CNC controlled milling, turning and eroding machines take over the data from the design section with the aid of a CAD-CAM link. In this way not only the production of new tools/dies but the manufacturing and supplying of replacement parts is ensured rapidly and reliably. After the new tools/dies have been assembled, they are tested and commissioned directly on the machines on which they will later be used.

However not only the designing and production of new tools/dies but also upkeep and preventive maintenance are core tasks of our tool-making department.