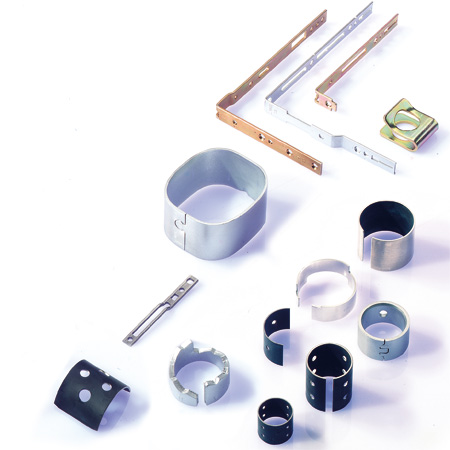

Punching-and-bending

Specialist for thick-wall bent parts with different hole patterns

Bending of strips of high thickness sheet metal

The bending of strips of high thickness sheet metal into sleeves and clinched tube sections is one of the core areas of expertise of our punching-and-bending section in which Bihler GRM punching-and-bending machines in the series 50, 80 and 100 as well as a Bihler BZ1 processing centre with hydraulic slides for maximum bending forces are employed. Through having automatic punching machines and Bihler processing centres working together, Dömer is in also in a position to produce thick-wall bent parts with the most different hole patterns. A specially developed tool technology makes possible different closure shapes of the part ends to meet the particular requirement. Tube sections closed and caulked with clinching means that for many applications no compromises are necessary in respect of functionality. On the other hand there is a cost advantage of up to 40 % in comparison with blanks sawn from long tube.

Bending of coated strip

In the field of bending technology, the name Dömer stands for very high process reliability. The combination of in-house developed bending tools and special lubricants permits manufacturing without striations or residues even with very sensitive surfaces. In this way the bending of coated and painted strip is mastered in a process-reliable manner. In addition the washing of the parts and cost-intensive coating of individual pieces are dispensed with.