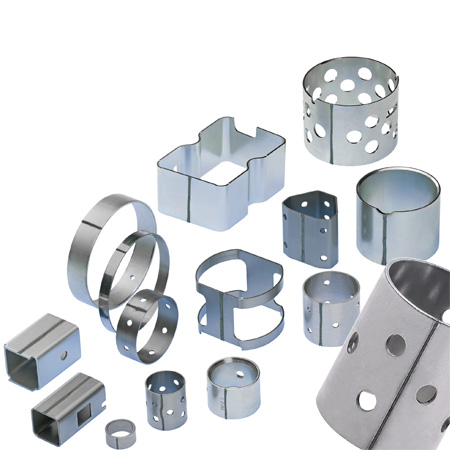

Welding by laser is a method for joining steel materials that has been established for many years. The integration of a solid-state laser unit with a capacity of 3.3 kW on a Bihler punching-and-bending unit makes possible the production of flexibly manufactured support, clamping and tensioning rings, tube sections (e.g. spacer tube, outer tubes) or, for example, the production of laser-welded bushes from sheet metal blanks shaped in any desired manner. Here diameters from 20 to 140 mm, widths from 10 to 60 mm and sheet metal thicknesses from 1 to 4 mm can be processed. With the aid of process integration, the "Dömerring" rings are able to be manufactured very cost-favourably through the use of application-matched steel qualities and the highly resilient, precision welded seam. Areas of application are found for these in the automotive industry, in the conveying and building appliance industries and in fact everywhere where conventionally manufactured tube/pipe sections are used for reinforcement.