The Dömerring

Innovative, versatile, flexible, highly resilient and cost-favourable

Product properties

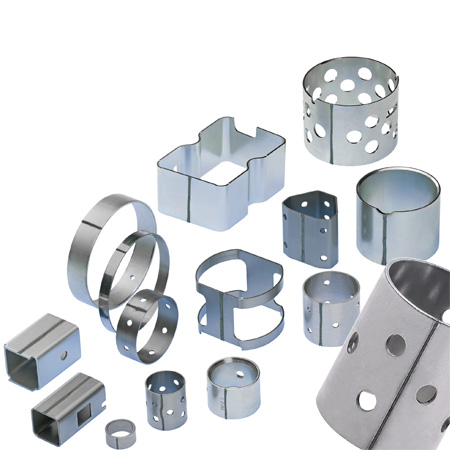

Able to be used in many different ways

- Support, locking, clamping rings

- Crimp rings

- Sleeves (inner sleeves, outer sleeves, spacer sleeves)

- Tube/pipe sections and pieces formed in any desired way

Flexible in respect of design

- Large, small: diameters from 20 to 140 mm

- Wide, narrow: widths from 10 to 60 mm

- Thick, thin: thicknesses from 1 to 4 mm

- Punched, closed: any desired free cuts in the jacket surface

Highly resilient

- Precise laser-welded seams

- Steel type in accordance with the particular requirement

Cost-favourable manufacturing

- Punching, bending, welding in one integrated process step

- Short cycle times

Optimal areas of application lie in the automotive industry, in the conveying and building appliance industries and in fact everywhere where conventionally manufactured tube/pipe sections are used. The Dömerring products offer high functionality with low manufacturing costs.

Technical details

The manufacturing of rings, bushes and sleeves can be carried out efficiently and economically with the aid of punching-bending technology. Here a strip of metal is cut to length and bent around a core. The two ends stand in front of one another in the form of a slot or are joined by clinching.

Our new process for the production of the Dömerring products goes a step further: the joint edges are joined together to a closed profile with a precise laser weld seam.

Thereby the production of the Dömerring products is a fully automatic process, consisting of the processes of punching, bending and laser-welding with the aid of which rings, sleeves, bushes and sections of any desired shape and form can be manufactured from metal strip in variable dimensions. In particular the sections generated in this integrated process are characterized by their absolute tightness and high strength whereby the economic efficiency of the manufacturing process is particularly marked with sections with pronounced hole patterns.